Effective Vacuum Degasser Strategies for Aquaculture Success

Introduction

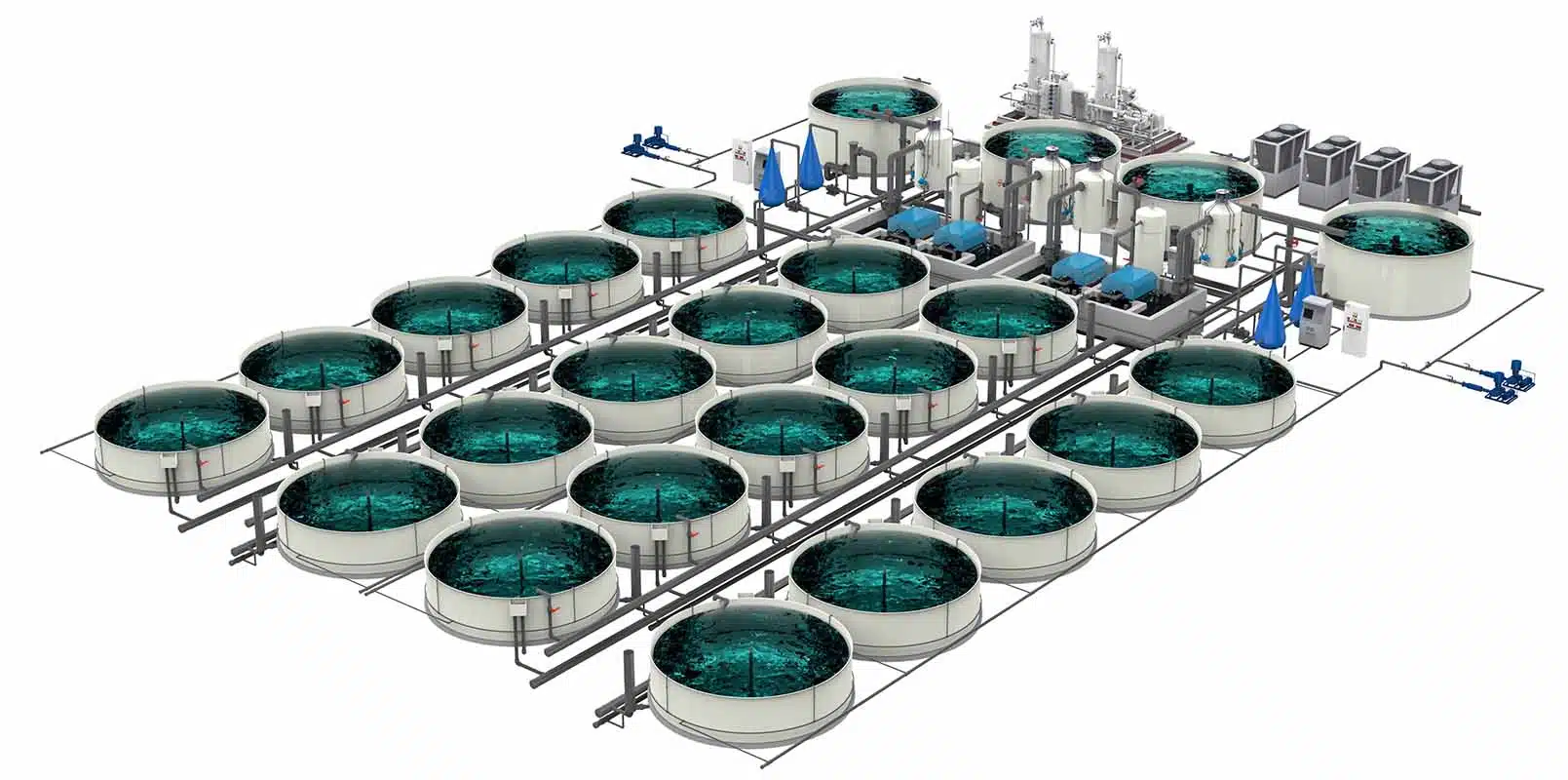

Ever tried keeping goldfish alive in a bowl for more than a week? Now scale that up to 20,000 live fish in a recirculating system. The difference? Professional-grade vacuum degassers that remove harmful dissolved gases before they become toxic.

In recirculating aquaculture systems (RAS), dissolved carbon dioxide (CO₂) and nitrogen can accumulate to dangerous levels. A vacuum degasser is your first line of defense against these invisible threats.

Why Vacuum Degassers Matter

In a closed-loop RAS, fish respiration and organic decomposition produce CO₂ faster than traditional aeration can remove it. High CO₂ levels (above 15-20 mg/L) stress fish, suppress immune function, and reduce growth rates.

Vacuum degassers work by creating negative pressure, allowing dissolved gases to escape from the water column. This is far more efficient than surface aeration alone.

Key Performance Indicators

- CO₂ Removal Efficiency: Quality systems remove 80-95% of dissolved CO₂

- Pressure Drop: Minimal impact on system hydraulics (typically 0.1-0.3 bar)

- Maintenance Frequency: Monthly inspection, quarterly cleaning

- Energy Consumption: 0.5-2 kW per unit depending on flow rate

Installation Best Practices

Position your degasser after biofilters but before oxygenation. This sequence ensures clean water enters the vacuum chamber and prevents re-saturation of treated water.

Flow rates should match your system turnover (typically 1-3 times per hour for intensive culture). Under-sizing leads to CO₂ buildup; over-sizing wastes energy.

Troubleshooting Common Issues

- Inconsistent Vacuum: Check for air leaks in seals and gaskets

- Reduced Efficiency: Clean packing media and verify vacuum pump operation

- Excessive Noise: May indicate cavitation or bearing wear

Conclusion

Investing in a properly sized and maintained vacuum degasser isn't optional for serious RAS operations—it's essential. The difference between stressed, slow-growing fish and healthy, market-ready stock often comes down to dissolved gas management.

Contact our technical team to discuss degasser sizing for your specific system requirements.